- 17 September 2024

- 4 min read

Window seal repair by yourself – DIY guide

When does a window seal need to be replaced?

How to fix window seal? A window seal needs replacement when you notice signs of wear or damage that compromise its effectiveness. Common indicators include condensation between double-pane windows, which suggests a broken seal allowing moisture ingress. You might also see visible cracks or gaps in the sealant, or feel drafts near the window, pointing to air leaks. Increased energy bills can also signal poor insulation due to failing seals, as more heating or cooling is needed to maintain indoor temperatures. Check for a distorted or cloudy appearance in the glass, which often occurs when seals fail and moisture accumulates. Regular inspections help catch these issues early, maintaining your window’s performance and home comfort. If you observe any of these signs, consider replacing the window seals to restore the functionality and efficiency of your windows.

Tools and material needed to fix the window seal

You need to perform a window seal repairs when you notice signs of wear or damage that compromise its effectiveness. Common indicators include condensation between double-pane windows, which suggests a broken seal allowing moisture ingress. You might also see visible cracks or gaps in the sealant, or feel drafts near the window, pointing to air leaks. Increased energy bills can also signal poor insulation due to failing seals, as more heating or cooling is needed to maintain indoor temperatures. Check for a distorted or cloudy appearance in the glass, which often occurs when seals fail, and moisture accumulates. Regular inspections help catch these issues early, maintaining your window’s performance and home comfort. If you observe any of these signs, consider replacing the window seals to restore the functionality and efficiency of your windows.

Window seal repair step by step

To fix window seal is a straightforward DIY task that enhances your home’s insulation and comfort. This step-by-step guide will walk you through the necessary tools and materials, and the process of effectively sealing your windows. Follow along to ensure a thorough and durable repair, keeping your indoor environment protected and energy-efficient.

Step 1: Inspect the window

Begin by thoroughly inspecting the window to identify all the areas where the seal is damaged or failing.

Step 2: Gather materials

You will need a caulking gun, silicone or polyurethane sealant, a putty knife, and cleaning supplies like rubbing alcohol and a clean cloth.

Step 3: Prepare the area

Clean the window frame and surrounding area where the sealant will be applied. Remove any old sealant using the putty knife, and clean the surface with rubbing alcohol to ensure it’s free of dirt and grease.

Step 4: Apply the sealant

Insert the sealant tube into the caulking gun. Apply the sealant evenly along the window frame where the old sealant was removed. Be sure to fill all gaps completely to create a tight seal.

Step 5: Smooth the sealant

Wet your finger or a smoothing tool and run it along the fresh sealant to press it into the gaps and smooth its surface. This helps in creating a clean, professional finish and ensures the sealant bonds well with the glass and frame.

Step 6: Clean up

Immediately clean away any excess or misplaced sealant with a damp cloth before it dries.

Step 7: Allow to cure

Leave the sealant to cure according to the manufacturer’s instructions—usually 24 to 48 hours. Avoid using the window during this time.

Step 8: Check and test

Once the sealant has fully cured, check around the window for any gaps or insufficient sealing areas. Test the seal by checking for drafts or moisture ingress.

What to watch out for when replacing a window seal?

When replacing a window seal, it’s essential to be mindful of several key factors to ensure the repair is effective and durable. Firstly, choose the right type of sealant; silicone sealants are popular for their flexibility and weather resistance, making them ideal for both interior and exterior applications. Polyurethane is another good option, especially for its strong bonding properties.

Make sure to completely remove all remnants of the old sealant from the window frame. Any residue can prevent the new sealant from adhering properly, compromising the seal’s effectiveness. It’s also crucial to ensure that the window frame and glass are thoroughly clean and dry before applying the new sealant. Moisture or dirt on the application surface can cause the sealant to fail.

Another point to consider is the temperature and weather conditions during application. Most sealants require a certain temperature range for optimal application and curing. Applying sealant in very cold or damp conditions can affect its curing process and its final resilience.

You might be interested in...

- Building advice

17 September 2024

What is the cost of converting a garage?

Cost of converting a garage into a room, for example, in the UK can vary basing on several factors. Typically, a basic garage conversion costs between £7,500 and £15,000. More extensive projects, including plumbing, electrical work, and high-end finishes, can range from £15,000 to £30,000 or more. Key factors influencing the cost include the size and layout of the garage, the quality of materials used, the need for insulation and heating, and compliance with local building regulations. Obtaining detailed quotes from local contractors is essential for an accurate estimate.

- Building advice

24 September 2024

Build a new house – how much money do you need?

To build a new house is a major investment, with costs varying depending on location, size, materials, and design. How much it is to build a new house, like really? In the UK, the average cost ranges from £1,800 to £3,000 per square metre, meaning a 3-bedroom house could cost between £180,000 and £300,000. Additional expenses include planning permissions, architect fees, and finishing touches like landscaping. This guide explores the factors that affect the total cost, helping you estimate how much money you’ll need for a new build.

- Building advice

- Gardening advice

17 September 2024

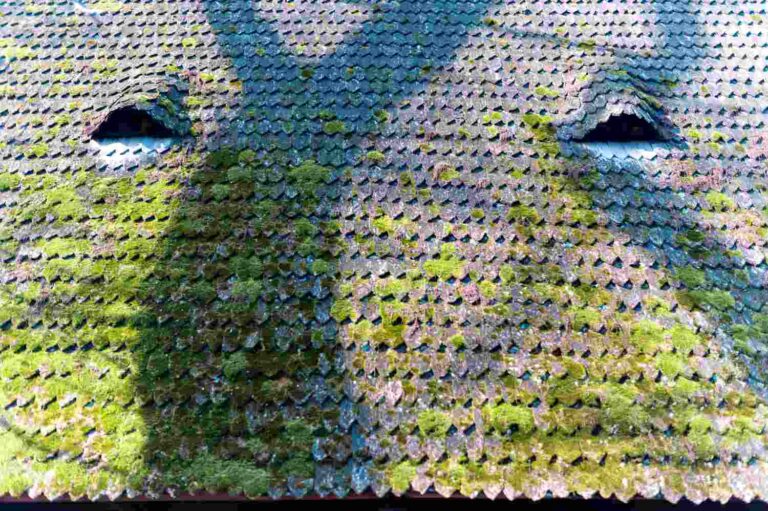

Using copper and zinc strips for moss control

Copper and zinc strips are effective methods for controlling moss growth on roofs. When rainwater interacts with these metals, it releases ions that inhibit moss development. Installing strips along the roof ridge allows these ions to wash down and protect the surface below. This method is eco-friendly and reduces the need for chemical treatments, making it a popular choice for long-term moss management.